Cold drawing machine chain structure and use method

Published:

2020-06-20

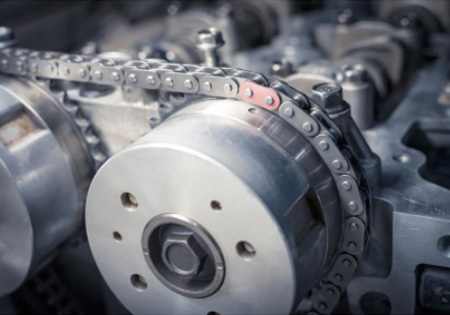

The cold-drawing machine chain is divided into the chain product series according to the basic structure of the chain, that is, according to the shape of the element, the parts and parts that mesh with the chain, and the size ratio between the parts. There are many types of chains, but their basic structure is only the following, and the other is the deformation of these types. We can see from the above several chain structures that most chains are composed of chain plates, chain pins, bushings and other components.

Chain structure of cold drawing machine:

The cold-drawing machine chain is divided into the chain product series according to the basic structure of the chain, that is, according to the shape of the element, the parts and parts that mesh with the chain, and the size ratio between the parts. There are many types of chains, but their basic structure is only the following, and the other is the deformation of these types. We can see from the above several chain structures that most chains are composed of chain plates, chain pins, bushings and other components.

How to use the cold drawing machine chain:

When the steel pipe is drawn, the entire inner chain plate enters the gap between the two teeth of the pentagonal wheel. When the driving wheel rotates in the W direction, the A end of the inner chain plate first meshes with one tooth of the pentagonal wheel, then the other tooth of the pentagonal wheel meshes with the B end of the inner chain plate, and the pentagonal wheel pushes the inner chain under heavy load The B side of the board advances. Because the rotation angle between the B-end hole of the inner chain plate and the pin shaft is greater than the A-end when drawing the steel pipe, under one-way gravity transmission, the hole wear on one end of the inner chain plate wears much faster than the other end, and a new inner chain plate is put in When the B end is pulled off, the hole wear of the A end is only about 5mm-8mm. If you continue to use it, soon the B-end hole will produce fatigue fracture. If it is turned around at this time (A, B ends facing the withered position), it can extend the life of the inner chain plate. The results show that it is feasible to use the chain puller of the cold drawing machine.

Selection of lubricating materials for cold drawing machine chain:

In order to reduce friction and wear between friction pairs, all friction-reducing substances that reduce frictional resistance can be used as lubricating materials. There are many types of lubricants, greases, solid lubricants, etc. When selecting the lubricant used in the chain drive, the lubrication mode, ambient temperature, and chain specifications must be considered. Generally, high-quality mineral oils with stable chemical properties are used, and those with pure ingredients, no oxidation, and no impurities are the best.

Related news

Tel

Tel

E-mail

E-mail

Fax

Fax

Address

Address